One Monitoring System Three Core Functions

Observation Agent, a monitoring system, features built-in functions such as cycle time detection, abnormal motion detection, and abnormal layout detection. It helps optimize production line efficiency, continuously improve product quality, and bring smart manufacturing into practical application.

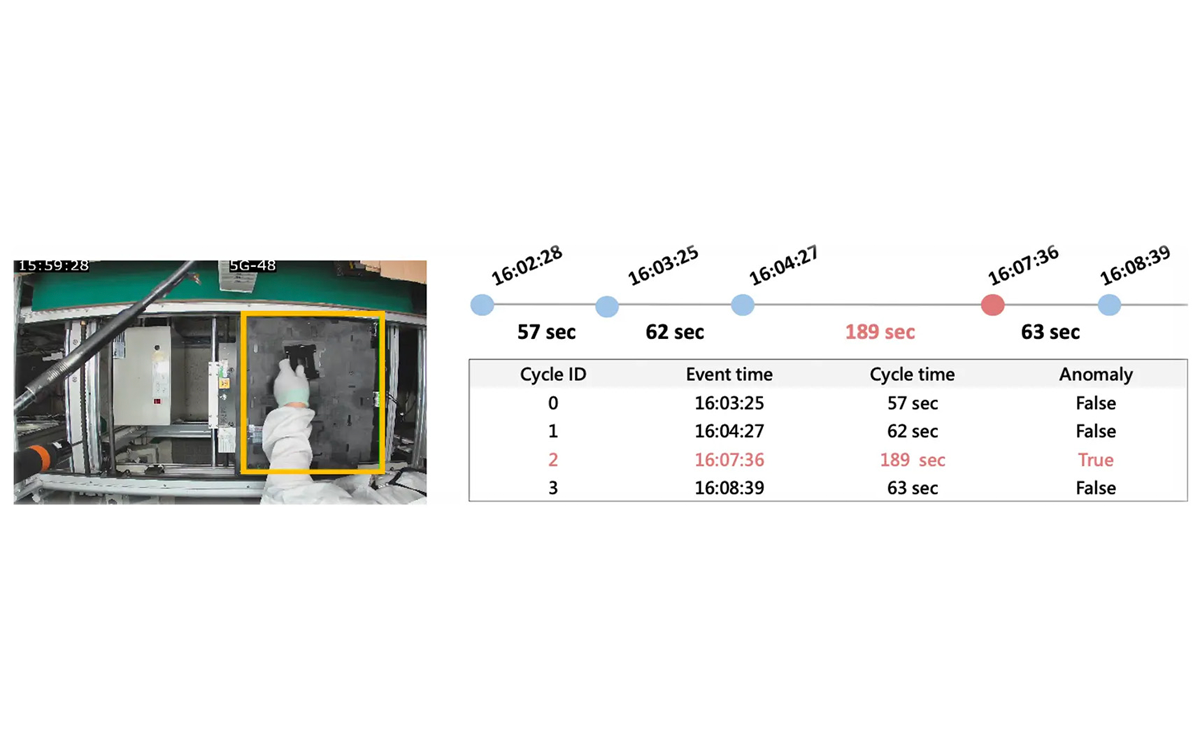

- Cycle Time Detection: The AI monitors the cycle time of repetitive tasks, automatically analyzes standard working hours, and provides data to managers. This assists in generating line balancing charts, enabling precise identification of bottleneck stations and optimization of production strategies.

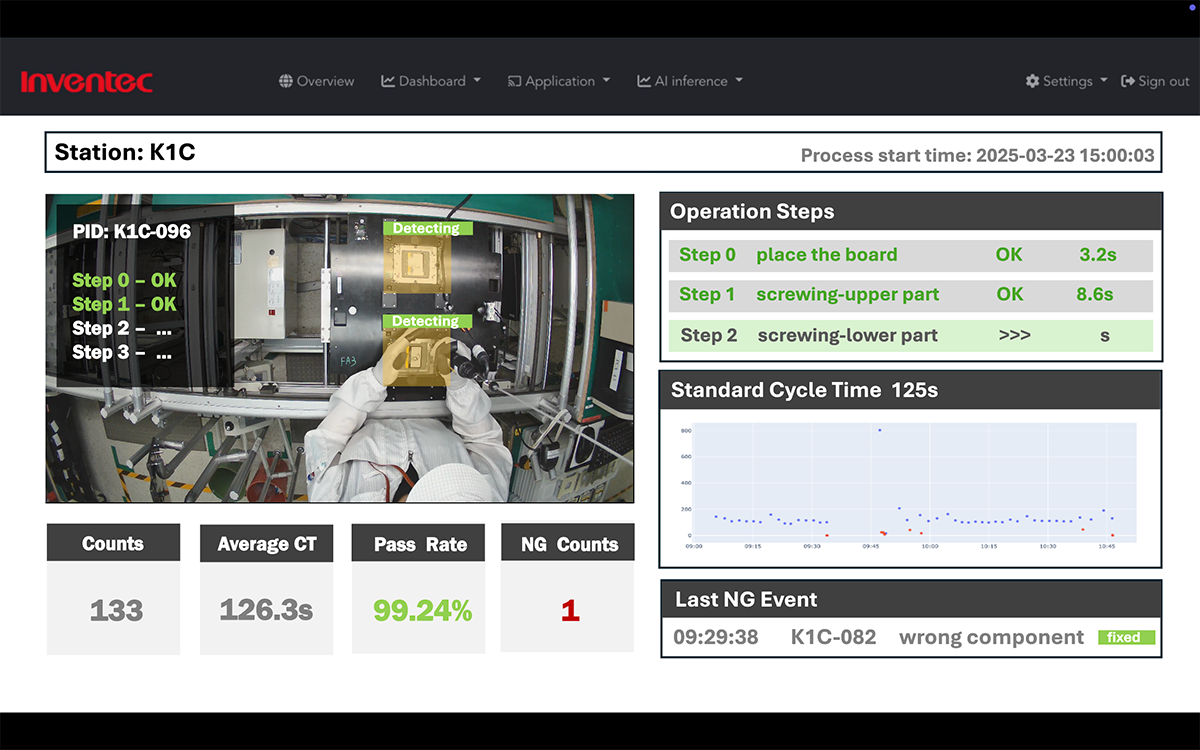

- Abnormal Motion Detection: The AI tracks personnel operations in real time, compares them against the standard operating procedures (SOP), and visualizes the comparison results on a screen. This helps monitor worker efficiency, effectively eliminate unnecessary movements, and enhance production line performance.

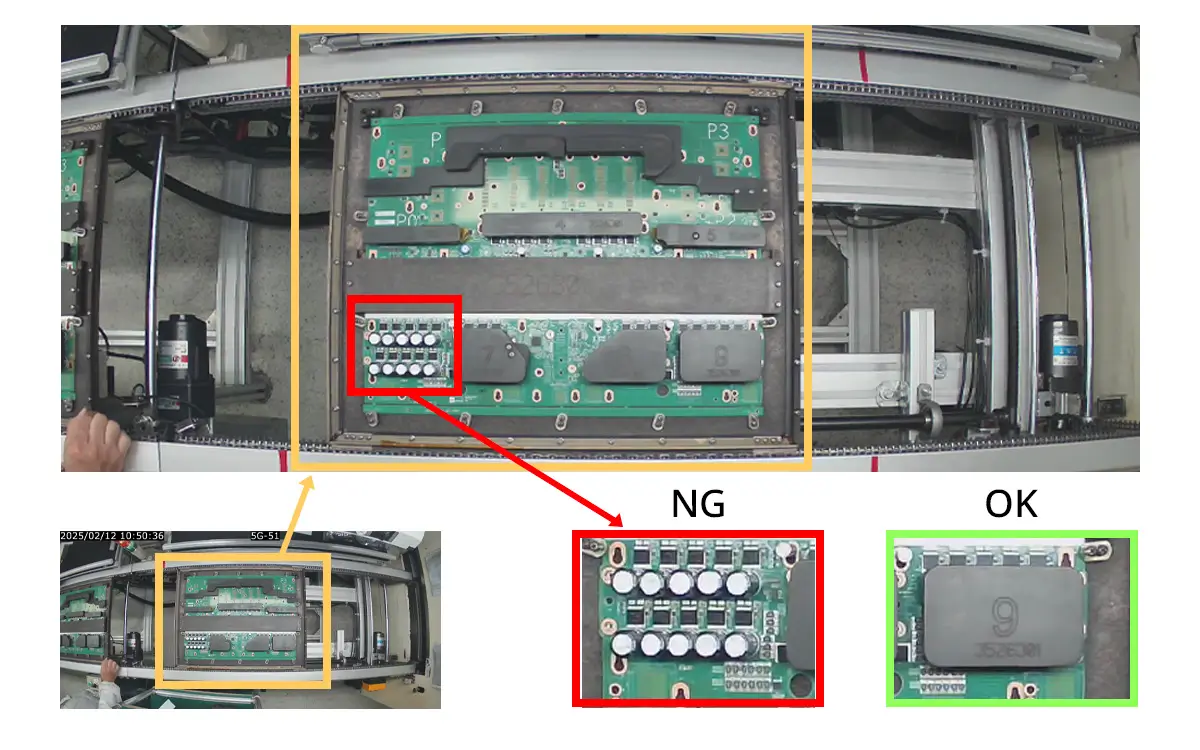

- Abnormal Layout Detection: With flexible configuration of inspection areas, the AI identifies abnormalities such as missing or incorrect components. This effectively reduces part scrap rates and rework costs, while improving the yield rate.

Benefit: Accurately identify bottleneck processes.

Benefit: Minimize unnecessary movements.

Benefits: Reduce part scrap caused by oversights and lower rework costs.

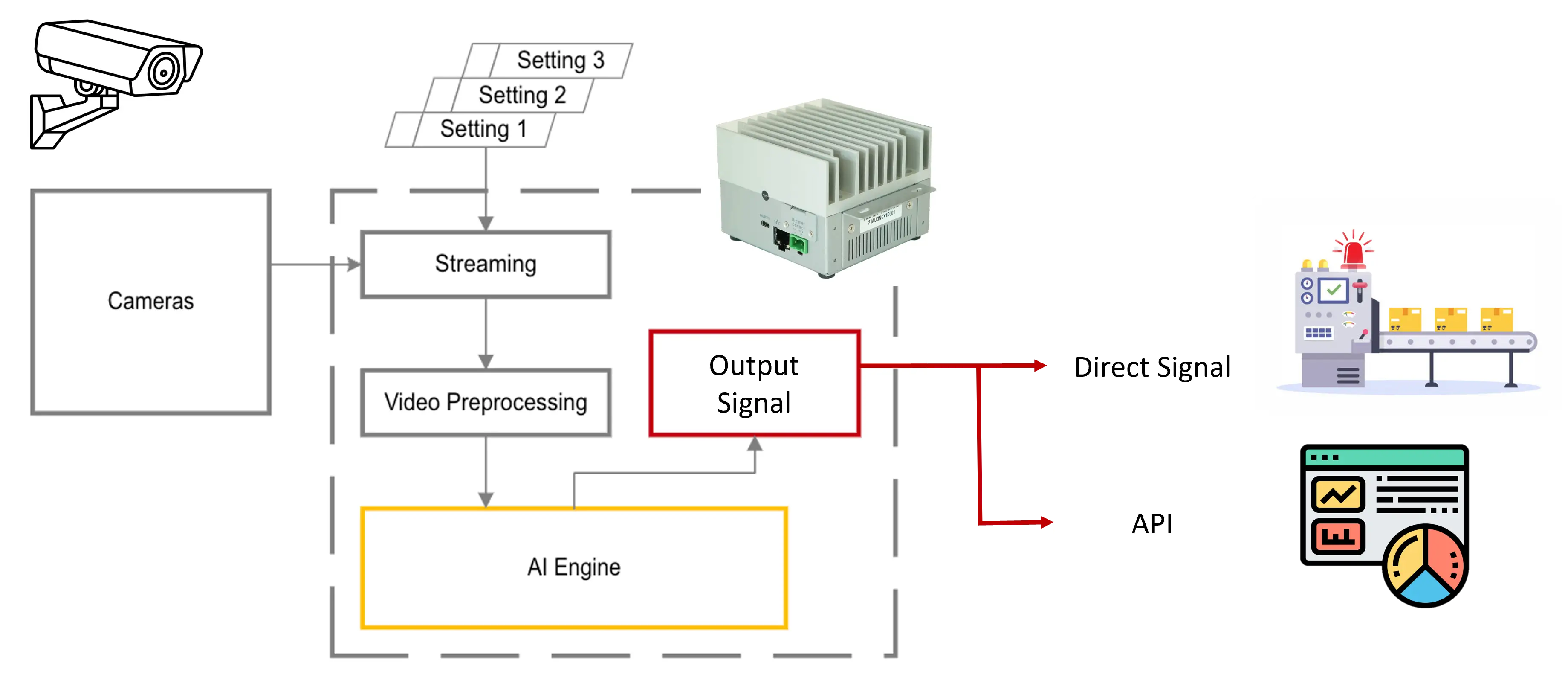

Plug and Play

Flexible to Deploy

All-in-one system design: One Edge Box (equipped with AI Self-Supervised Learning (SSL) technology) and a single camera are needed to get the system up and running. Featuring plug-and-play functionality, it offers high deployment flexibility—making it ideal for rapid rollout across entire factory sites.

- AI Self-Supervised Learning (SSL) Technology: Eliminates the need for large datasets and reduces the labor cost of data labeling, enabling high-performance, efficient management of small and diverse data.

- Real-Time Anomaly Handling and Alerts: This system can be directly integrated with the production line to immediately halt operations in the event of an anomaly. Alternatively, it can connect to enterprise production monitoring platforms via API technology, automatically sending real-time alerts to relevant personnel when issues occur.

- Low-Barrier Implementation: With its all-in-one system design, deployment requires only one Edge Box paired with a single camera to get up and running.

- Highly Flexible Deployment: From small-scale applications to full-factory implementation, the system allows for equipment to be added as needed, enabling scalable and adaptable smart production monitoring.

Camera: A resolution of 4 megapixels or higher is recommended. However, the product’s AI offers high adaptability and can be evaluated based on actual application needs.

All-in-one System

IP Camera + Edge Box + Output Signal