AI + AOI Inspection Increasing Customer Satisfaction

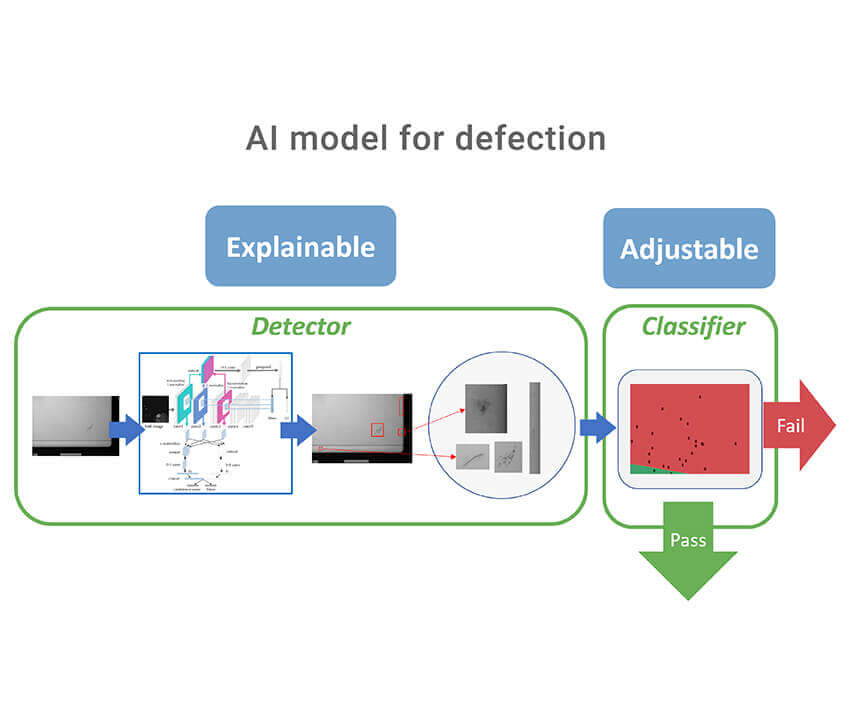

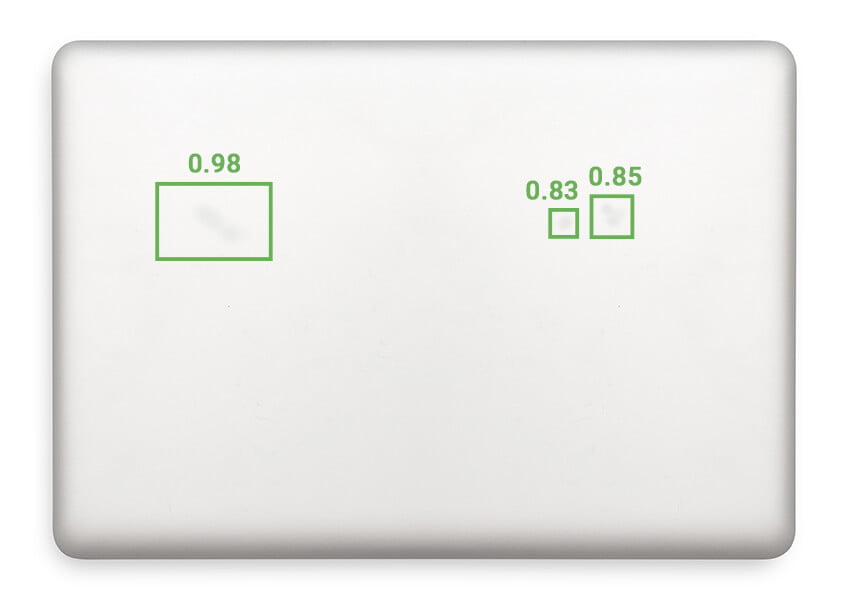

- High Accuracy: Built-in Inventec AI technology, performing higher accuracy than human inspection, being excellent for Quality Management.

- High Efficiency: Taking only few seconds, from taking photos to AI analysis, optimizing production line.

- High Universality: Equipped with a structured AI database to apply different quality standards for different product models.

- High Reliability: enhancing consistency in defect detection about 15% to increase customer satisfaction.

Digitalization in Quality Management Realizing Industrial 4.0

- Supporting Laptop Surface Appearance Detection system connecting to Manufacturing Execution System by API for realizing industrial 4.0 in manufacturing.

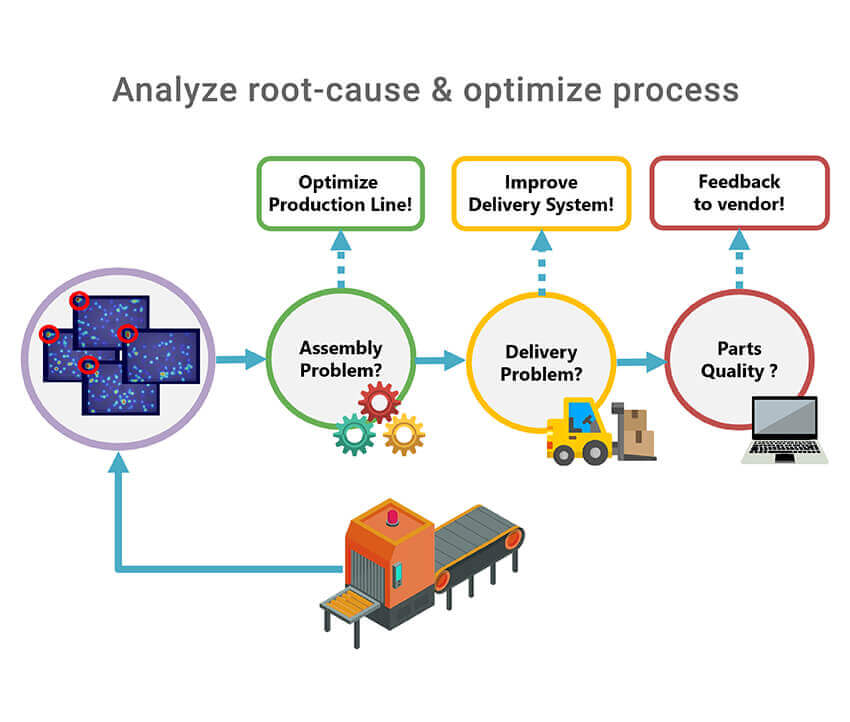

- Built-in AI-assisted automated data labeling, enable find rare and unclear defect types for analyzing root-cause and optimizing process.

- Recording and saving the defect data, automatically, for improvement of data completion to optimize quality management system.

Distinguished Capability of AI in Smart Manufacturing

- Publication:

- Edge AI in Smart Manufacturing: Defect Detection and Beyond (GTC 2019)

- Toward Taming the Training Data Complexity in Smart Manufacturing (GTC 2020)

- TrustMAE: A Noise-Resilient Defect Classification Framework using Memory-Augmented Auto-Encoders with Trust Regions (WACV, 2020)

- Demystifying Data and AI for Manufacturing: Case Studies from a Major Computer Maker (APSIPA, 2021)

- Domain-Generalized Textured Surface Anomaly Detection (ICME, 2022)

- IP (Taiwan、China and USA) :12